Originally invented in 1995, blast chillers and freezers have become a staple for the food industry. Built to quickly chill cooked products, the chillers reduce the possibility of harmful bacteria growing in the danger zone between 5ºC and 60ºC.

Dishes that require fast cooling:

- Dishes that are cooked by the Cook and Chill process.(quiches, lasagne, meat, vegetables)

- Desserts/pastries that require cooling.(creams, desserts, pies, cakes, puddings)

- Dishes using hot preparations which are processed in Cook

In addition, unlike standard refrigeration, a blast chiller extends the shelf life of the products, reduces moisture loss, and preserves products’ flavours and textures.

Blast Chillers increase productivity within commercial businesses allowing staff to work more efficiently thanks to the streamlining production process.

Your blast freezer is working hard for you, so it's only fair if you do the same, right? Let's look at a few best practices to give back to your blast freezer, ensuring it's running in top form.

Cleaning your Blast Chiller

Clean your blast chiller daily. Any spills or drippings need to be wiped away immediately to reduce build-up. We recommend using mild soap and warm water to clean the inside, door gaskets and use a stainless-steel polish occasionally on the outside.

During the cleaning process of the Chiller, ensure that no accidental damage has occurred and gone unnoticed, and all functions correctly work such as door gaskets closing firmly. Should damage happen to components such as door gaskets, it could impact the internal temperature and negatively affect products.

Airflow

Airflow access (intake and exhaust) needs to be in a well-ventilated area. If the airflow is blocked, for example, if there are too many boxes stacked up, that will only make the blast chiller work harder, wasting energy and reducing the unit's life.

With current events heightening the costs and overhead for businesses, it’s important to ensure costs are fully optimised and as such no unnecessary expenses are being accrued.

Pre-Cooling Tips

Pre-chill your blast chiller for 30 minutes before putting the first load in to avoid the refrigeration system being overworked, and this will also ensure that the cycle will complete on time.

By pre-cooling the blast chiller, you can also be certain that the temperature has reached the correct temperature for the moment food is placed into the chiller. This leaves peace of mind the product is efficiently cooling.

Use a Food Probe

Using a food probe will help stop your cycle when the correct temperature is reached. Place the probe in the densest part in the middle of the products to have the most accurate reading, and this will avoid over and under-chilling.

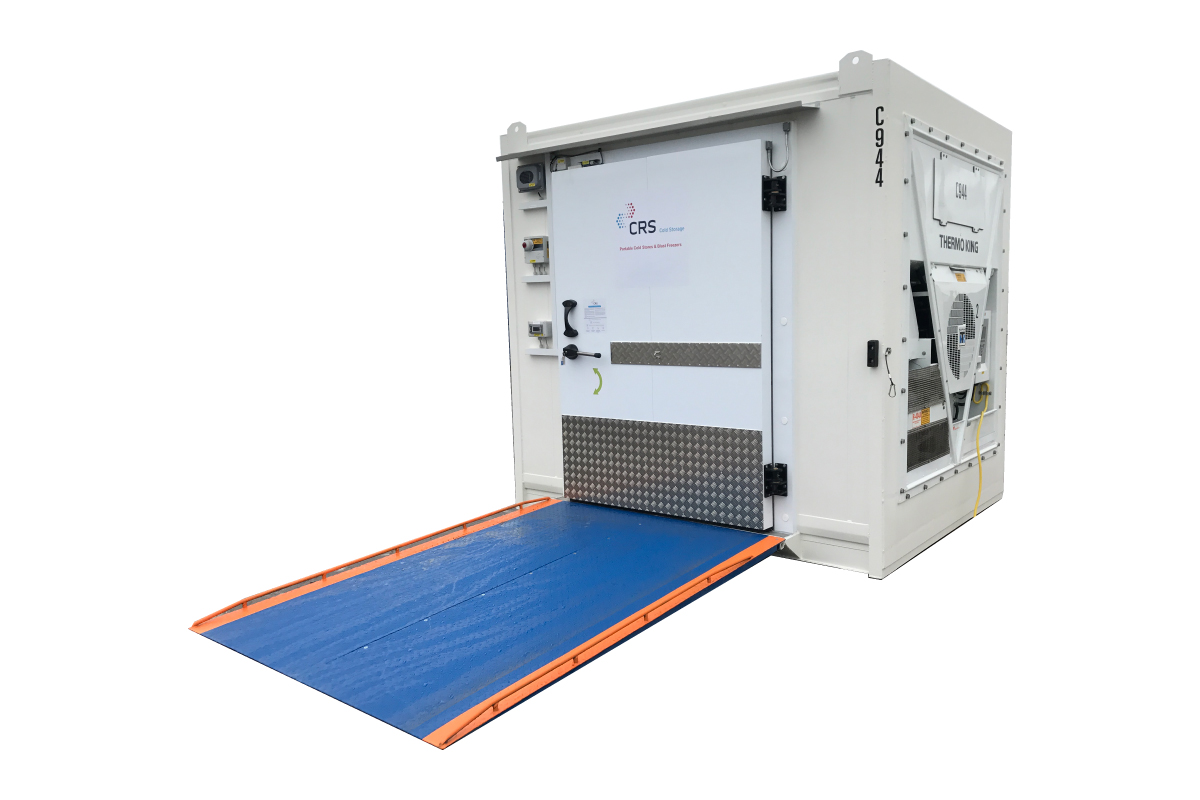

Our first unit was ordered, delivered, installed and working within 48 hours. We decided to upgrade to a permanent 40’ unit after 12 months as reliability, flexibility and value for money were more appealing than buying a static freezer. We were very happy with the equipment provided and with the service provided by CRS."

Beckworth Emporium

Keep the Blast Freezer Door Closed

Keep the door closed once the food is in and your system is on!

Once the blast has started and you open the door, not only does this subject the food to warm air and disrupt the whole cycle, but it also compromises food safety.

Don't Cover food

Your blast chiller has a specific airflow designed to protect even delicate products. Covering your food will only hinder the blast cycle and increase cooling times by thirty minutes.

Get in touch with our specialists today and discuss the best practices of CRS recommended blast freezers specifically for your business.